In the wake of the immense popularity achieved by Gold Rush, Discovery channel expanded the franchise with various spin-offs, one of which is the thrilling Gold Rush: White Water. Debuting in 2018, this series follows ‘Dakota Fred’ Hurt and his son Dustin as they dive into treacherous waters, venturing into the depths in search of elusive gold nuggets.

Extracting gold from underwater environments poses significant challenges. Miners must contend with swirling river currents, grapple with rocks submerged deep under the surface, and transport heavy equipment across rugged terrain.1 Over the span of nine gripping seasons, the crew of Gold Rush: White Water has navigated numerous obstacles, each presenting unique twists and additional hurdles. To keep their operations afloat, the team has consistently devised innovative engineering solutions tailored to the challenges they encounter.

Innovative Engineering Marvels of Gold Rush: White Water

1. Motorized Trolley System (Season 4, Episode 2)

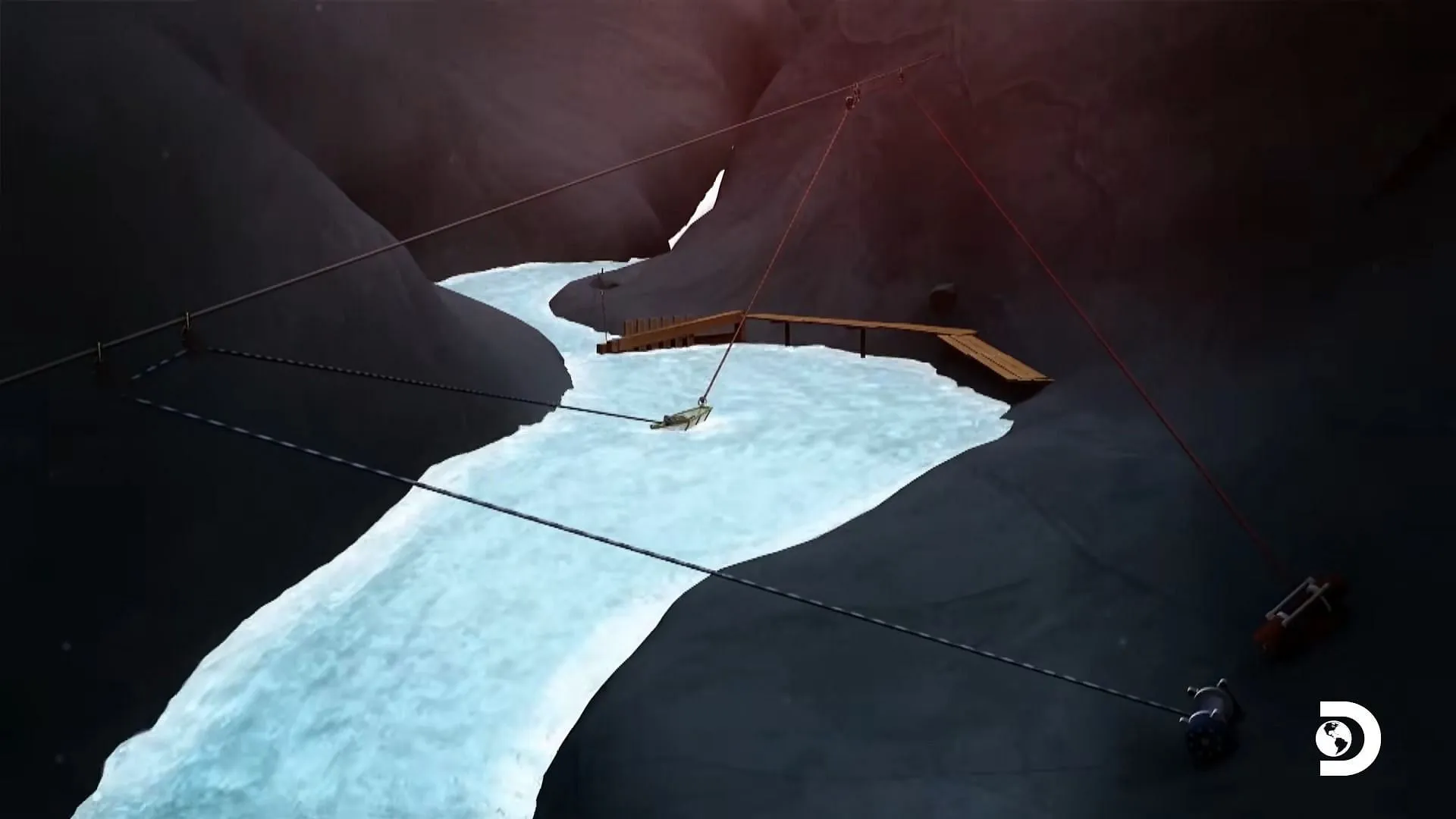

In season 4, episode 2 of Gold Rush: White Water, the crew faced the challenge of transferring equipment from their campsite to a dive site over a daunting 600-foot distance above a steep valley. To solve this logistical nightmare, they engineered a motorized trolley system, featuring a platform suspended from a half-inch steel cable that hung 400 feet above ground.

Dustin Hurt took the reins at the campsite, operating the trolley with a lever that controlled the platform’s speed. To ensure safety, he started by testing the system with lighter materials, progressively advancing to heavier loads, including motors and assorted utilities. However, Dustin soon realized the pace was escalating beyond his control, prompting crew member Wes Richardson to step in and manage the final equipment transfers.

2. Rock-Sled Pulley System (Season 4, Episode 10)

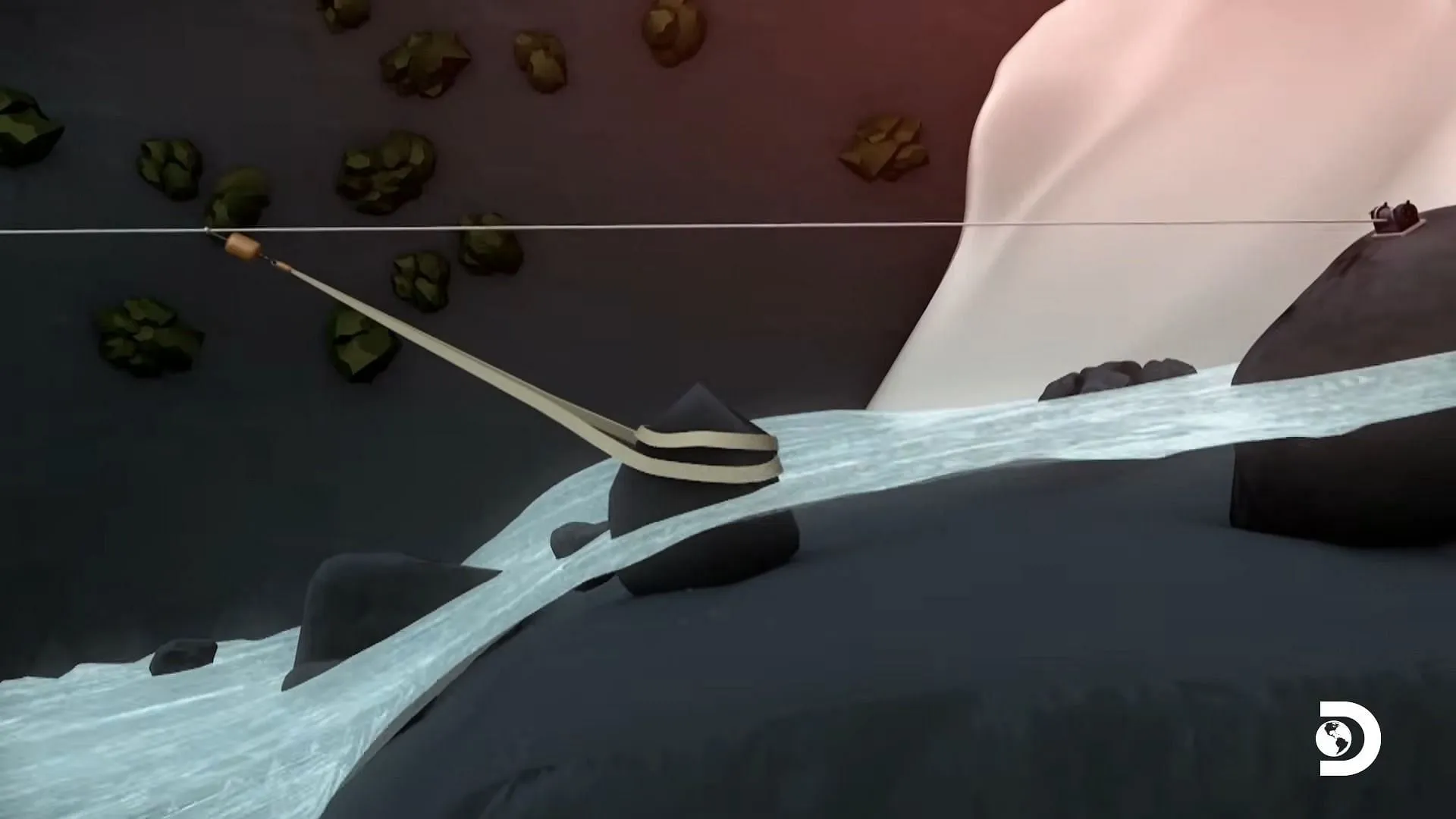

During season 4, episode 10, the crew encountered a challenging task: extracting rocks from a moderately deep river adjacent to steep mountain terrain. To address this issue, ‘Dakota Fred’ conceptualized the Rock-sled pulley system, which transformed their dragline setup into an innovative vertical lift mechanism.

By attaching a double block pulley to the skyline and routing the downstream winch through this pulley, the team could successfully lower a custom-made basket designed specifically to haul rocks from the dive hole. This basket featured a sled that was one foot shorter and ten inches narrower than their existing apparatus.

“Now we can’t maintain our ramp for the sled to go up. We’re going to have to pick vertical out of the hole just like a basket, except this happens to be available,”Fred pointed out.

The plan proved successful, allowing the crew to systematically remove rocks and continue their quest for gold below.

3. Redirected Winch System (Season 6, Episode 5)

In season 6, episode 5, the team found themselves confronted with a significant obstacle at the Golden Gates, where their existing winch system was inadequate for moving large boulders. In response, Dustin proposed a series of modifications that would enhance their winch’s performance.

Wes replaced the polyethylene rope with a more robust 1/4-inch steel cable that minimized snagging on jagged rocks and upgraded the key winch to a unit capable of double the pulling power. Despite these advancements, some boulders remained immovable, as the redirect position of the lower winch was drawing the rocks deeper into the riverbed.

After assessing the situation, the crew decided to elevate the winch’s position by 25 feet. This adjustment proved effective, allowing them to efficiently lift the stubborn boulders and clear the path for their dredging operations.

As the adventures of Gold Rush: White Water continue to unfold, viewers can catch new episodes every Friday on Discovery, showcasing the relentless spirit and ingenuity of those who dare to chase gold in challenging environments.